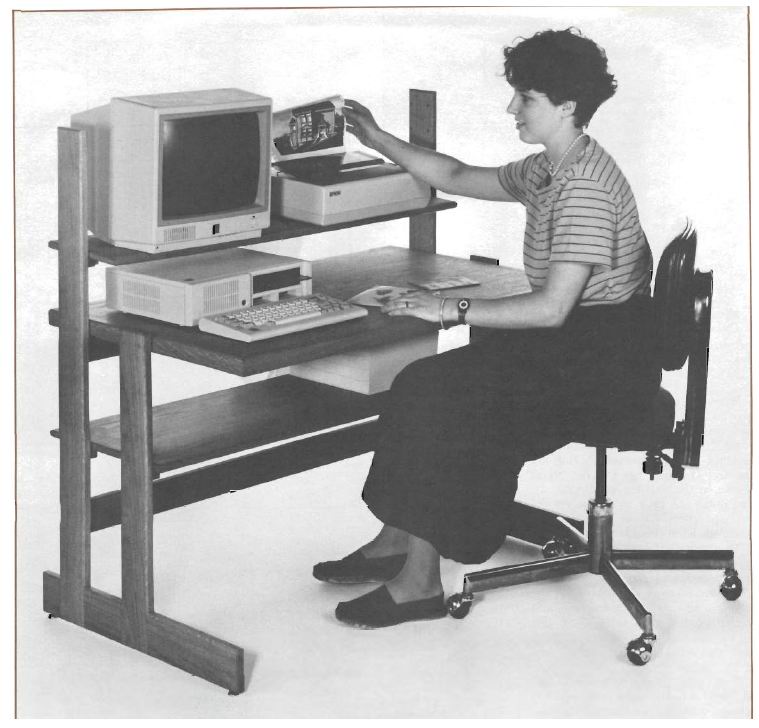

Computer Desk . part 2.

Понедельник, 9 января, 2012The computer desk is easy and inexpensive to build. Although we used oak, both for its strength and because oak veneer plywood is commonly available, almost any hardwood can be used. As shown in the plywood cutting diagram (Fig. 1), all the plywood pieces (the three shelves: parts A, B, and C; and the main shelf backing strips: parts D and E) can be cut from one half sheet of plywood. All the other parts for the desk can be cut with the table saw from standard 3/4 in. stock, When cutting the plywood use a plywood blade to provide a smooth cut and help prevent chip-out along the edges. Next, cut all the hardwood components, parts F through P. Half-lap the feet (L) and legs (M and N) as shown in the half-lap detail (Fig. 2), and notch the back legs to accept the two stretchers (O) as shown in the stretcher detail (Fig. 3).

(далее…)